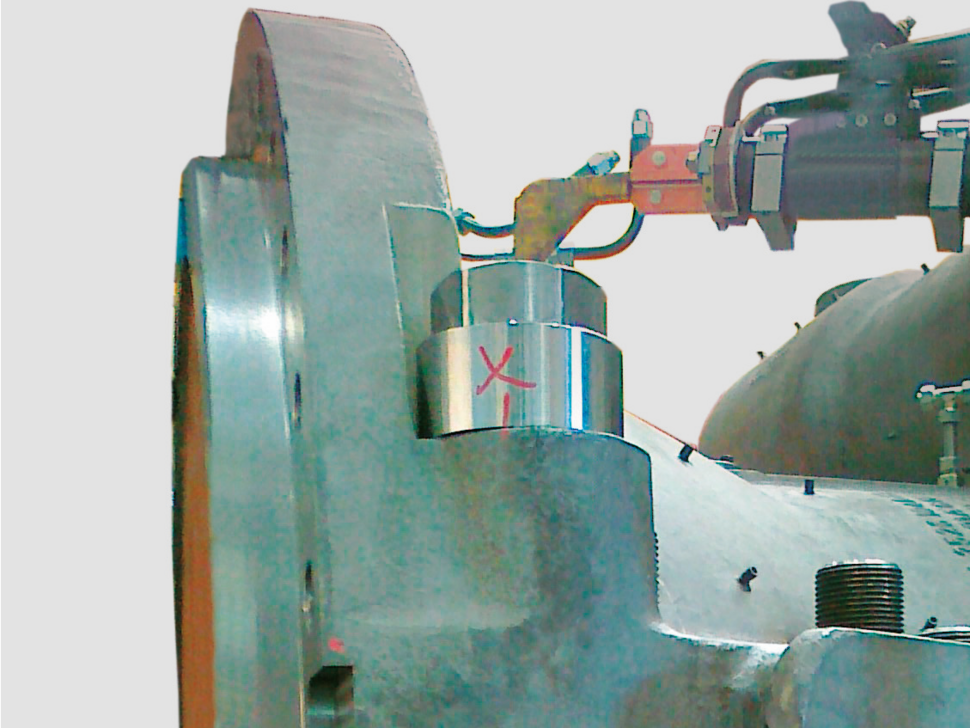

Heating expansion bolts

Expansion bolts are used to secure housings and shaft-hub connections, especially in power station plant installation and their maintenance inspection. A line inductor inserted into the hollow bolt is used to heat and expand it. After heating to the required temperature, the securing nuts are now tightened. After the bolt has cooled down, steam turbine housings or wind turbine hubs are firmly secured. To release the connection, the expansion bolt must be heated again.