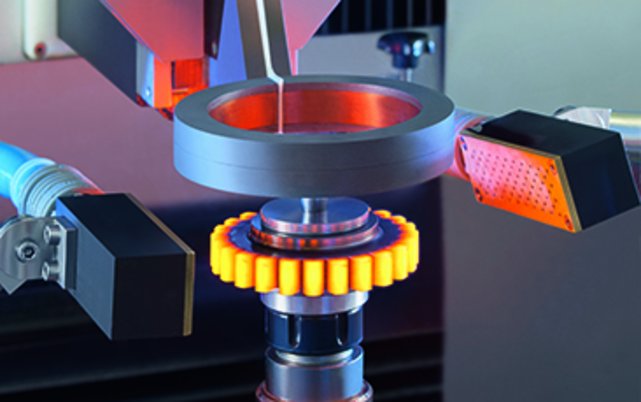

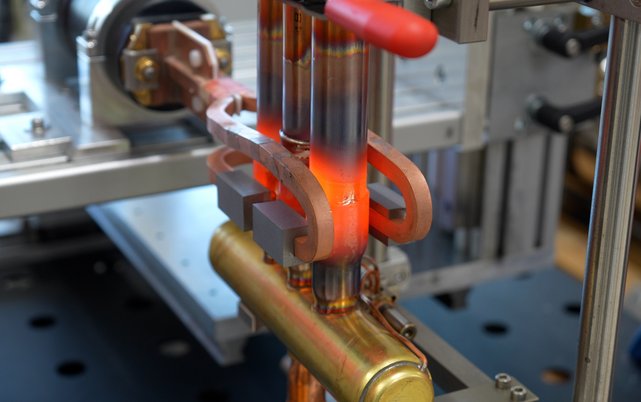

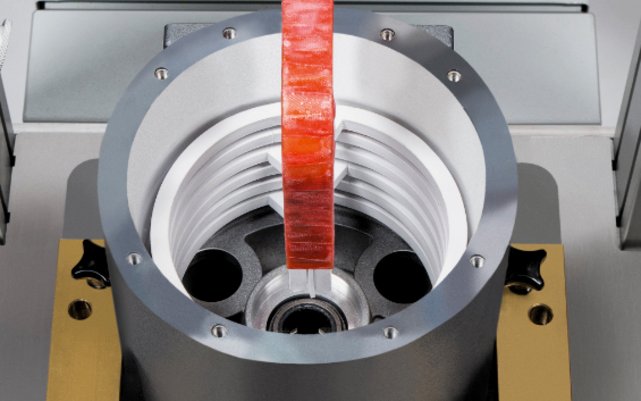

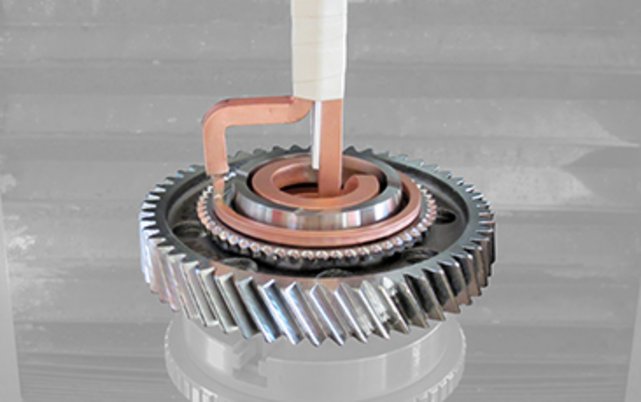

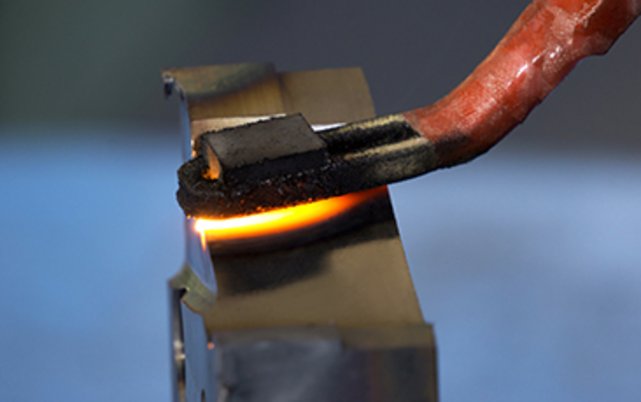

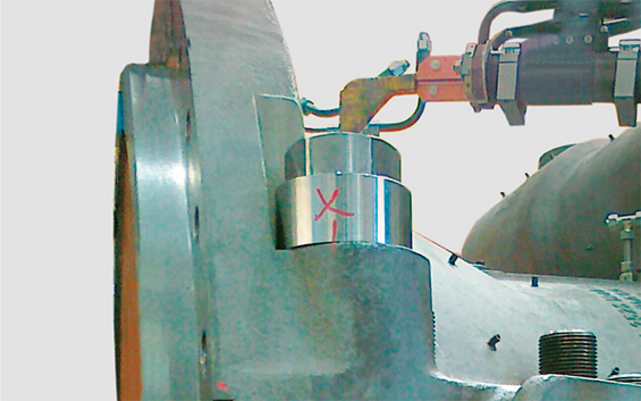

Induction - heat where it is needed

Targeted non-contact energy input, process data recording at part level, full line integration if required, maximum energy efficiency, precisely reproducible quality as well as gas and CO2 emission free - these are the advantages of induction heating. These are increasingly used, for example, for surface hardening, soldering, shrink-fitting & releasing, stress-relieving or pre- and post-heating.