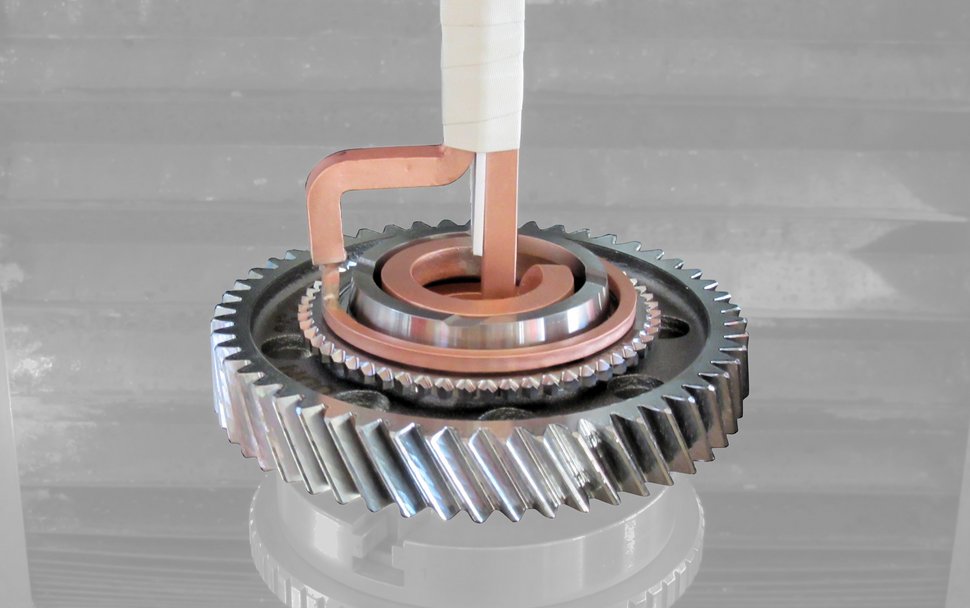

Heating for welding processes

All welding processes have one thing in common: the risk of microcracks forming. Thanks to induction pre- and post-heating, components can be brought to a designated input temperature. Stress peaks in the material and the resulting formation of cracks, especially during cooling, are avoided and process times are often reduced. All this with high precision, so that negative effects on the material structure can be excluded. Flame heating cannot guarantee this consistent level of precision.