Brazing and shrink-fitting with manual or semi-automated systems

UNI HEAT and UNI BRAZE are complete heating systems that are configured into individualised solutions based on standardised assemblies and components. The application focus of these products is on shrink-fitting electric motor components, and soldering a wide variety of components. The degree of automation depends on the customer's requirements: from manually loaded fixtures for small batches to partially or fully automated systems for large batch quantities. Various process monitoring options - from temperature control to eQC modules for I4.0 connection (eldec Quality Control) - ensure full reproducibility of the heating process.

Heating and shrink-fitting of gears on motor shafts

The helical spur gear and the electric motor are loaded and unloaded manually. Temperature monitoring via pyrometer. Automatic joining feed and cooling to target temperature. Operation via handheld display with touch screen.

Generator: SYSTEM-LINE M 30.

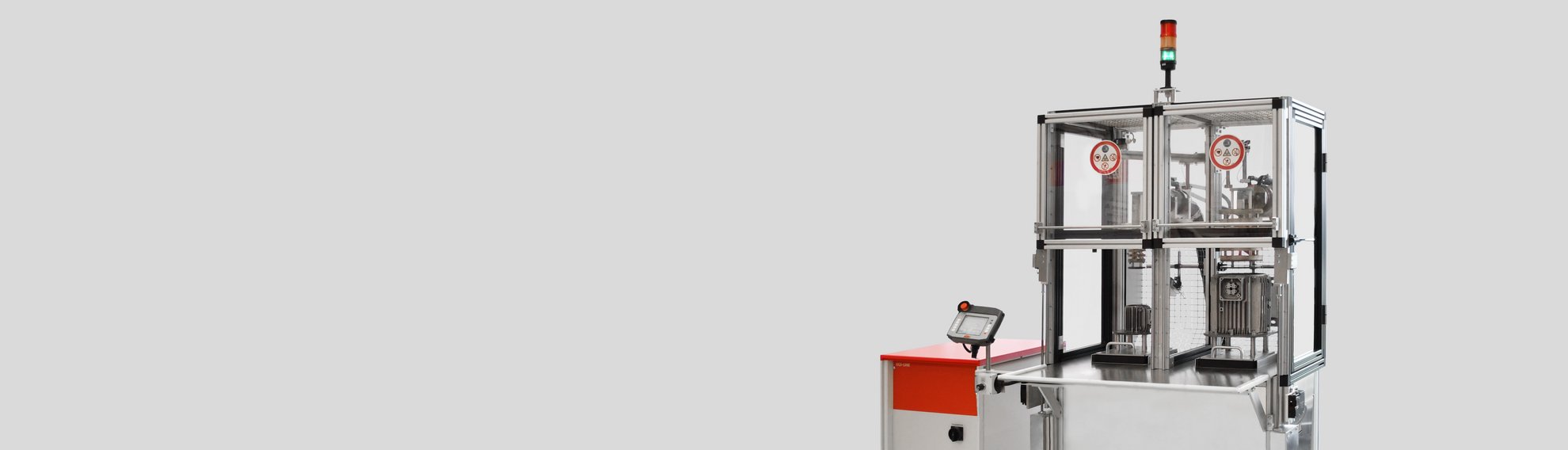

UNI HEAT: Heating of two electric motor housings

Heating of two electric motor housings to shrink-fit temperature with automatic feeding of the workpieces into the inductors. While one housing is being heated, the other can be loaded and unloaded manually. Operation via handheld display with touch screen.

Generator: SYSTEM-LINE L 75 2A.