Technologies and solutions for a variety of industries

eldec induction generators, hardening machines and inductors are used in a wide range of industries. The most advanced technology combined with many years of application know-how form foundation of solutions for our customers' tasks. With this combination of high-quality product and competent service, we have earned an excellent reputation worldwide in a wide variety of industries and applications over the past decades.

Automotive: electric and combustion vehicles

Induction heating has a long tradition in automotive engineering, both in the production of components for combustion vehicles and now increasingly for electric vehicles. Typical applications are hardening, shrink-fitting, soldering and bonding processes.

In recent years, eldec has supplied machines and generators for the manufacture and assembly of, for example, balancer shafts, camshaft systems, input and output shafts, constant velocity joints, bearing journals, steering components, wheel hubs, powder metal components, EV rotor shafts, body panels, fuel and cooling lines, rotor packs, stators and battery components.

e-Bikes

Urban, in nature, as a form of transport or transport vehicle, for leisure or work: e-bikes have rapidly gained in importance in recent years. In recent years, eldec has supplied machines and generators for the manufacture and assembly of transmission components, input and output shafts, rotor packs, stators, and battery components.

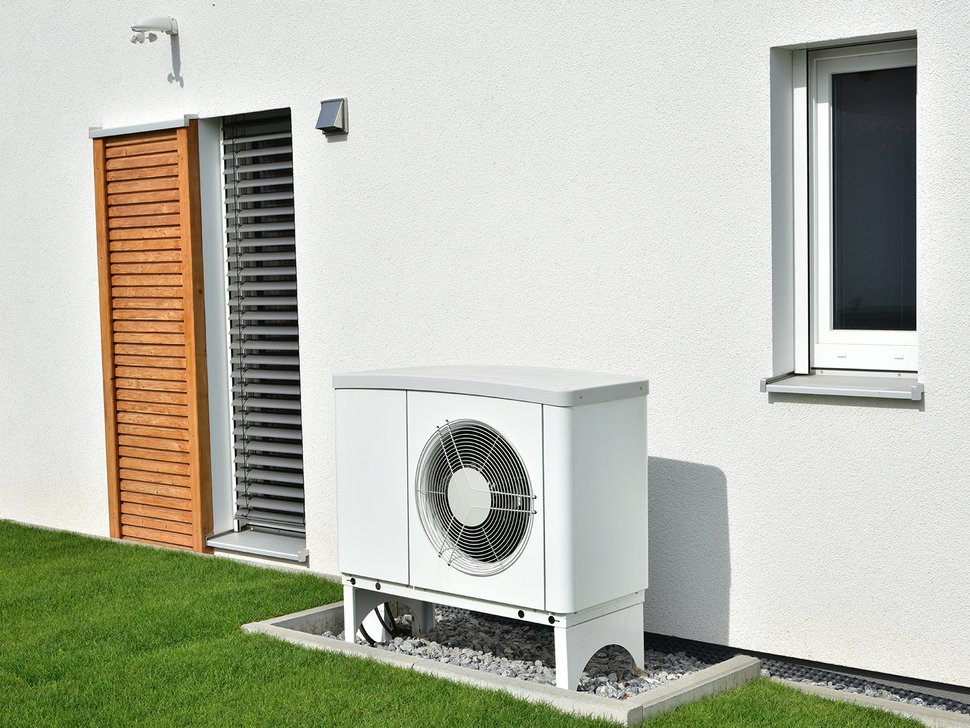

Heating construction

Driven by the search for environmentally friendly and energy-efficient production processes for the manufacture of copper tube brazed joints, the gas flame is increasingly being replaced by induction heating. Thanks to the precise application of energy, each soldered joint on heat pumps, heat exchangers and air-conditioning units is of the same reproducible and consistent quality, and this with enormously increasing quantities, and increasingly automated production.

White goods

The "white goods" industry is also increasingly oriented towards energy-efficient and environmentally friendly production processes, so that induction is increasingly being used instead of the gas flame to produce copper tube soldered joints as well as shrink-fitting and other heating processes.

The energy is applied efficiently and precisely to each component, ensuring consistent quality: Every heating process applied to components for refrigerators, freezers, washing machines, dryers and dishwashers is reproducible and consistent.

Aerospace

The basic physical principle of induction heating is also used when building aircraft. Due to the limited geometric constraints and exact precise energy input, only minimal distortions occur when heating aerospace components. The ability to comprehensively document numerous in-process data at part level is of utmost importance especially in aerospace, particularly when hardening engine components and auxiliary units as well as shrink-fitting during numerous assembly processes.

Power plant construction

Induction heating plays an important role in the construction of new power plants as well as in maintenance work and complete revision of power plants: hardening and shrink-fitting of steam turbine components, tightening and releasing housing elements, threaded connections, and pipe joints. eldec technology is also used in the dismantling of nuclear power plants.

Renewable energies

As in conventional power plant construction, induction heating plays an important role in new construction, but also in maintenance work and complete overhauls of hydroelectric power plants, solar thermal steam turbines, and wind turbines. Hardening and joining of steam turbine components, tightening, and releasing housing elements, threaded connections and pipe joints as well as soldering of copper components such as transformer plates, pipe joints and braded wires in a wide range of sizes. Induction is also used in the manufacture of solar cells, especially in the production of the requisite semiconductors and contactors.

Agricultural and construction machines

Basically, induction heating technology is used in agricultural and construction machinery for similar components to those used in ICE car manufacturing, only all a size larger. In addition, mobile hydraulic systems are often used; as such, pump components, drives and cylinders are induction hardened and shrink-fitted. Carbide cutters are used in road building and mining, the cutting inserts are induction brazed into the steel bodies.

Mechanical Engineering

Induction heating is used in a variety of ways in classic mechanical engineering, such as in the manufacture of tooling, presses, or sheet metal processing machines: surface hardening, shrink-fitting, soldering, cutting edge hardening are the typical applications for components of the most varied geometry, size, weight, and material type.

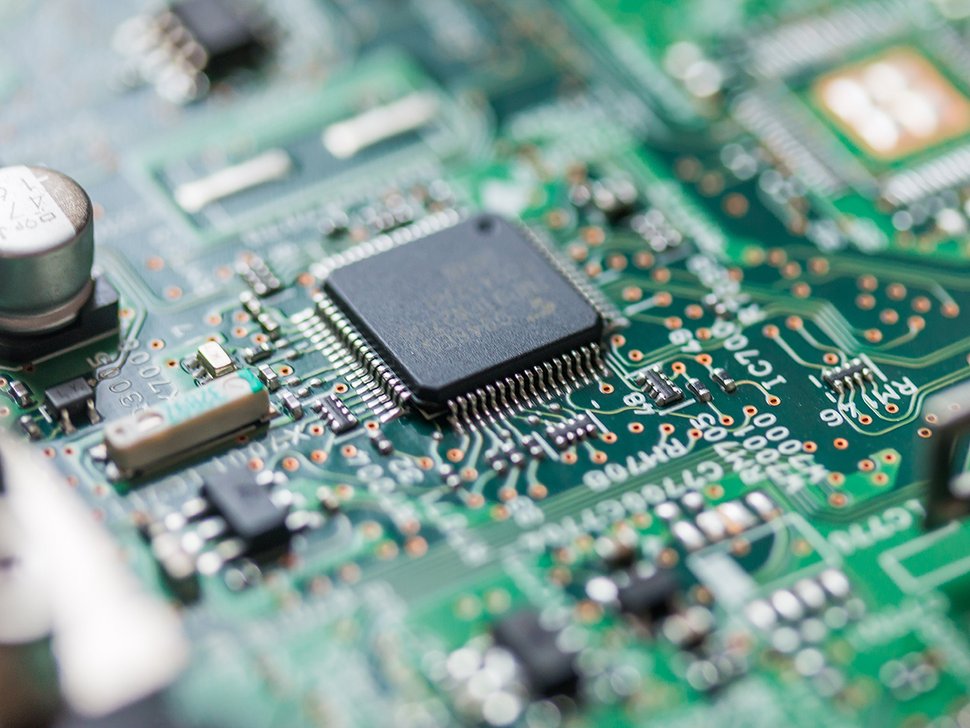

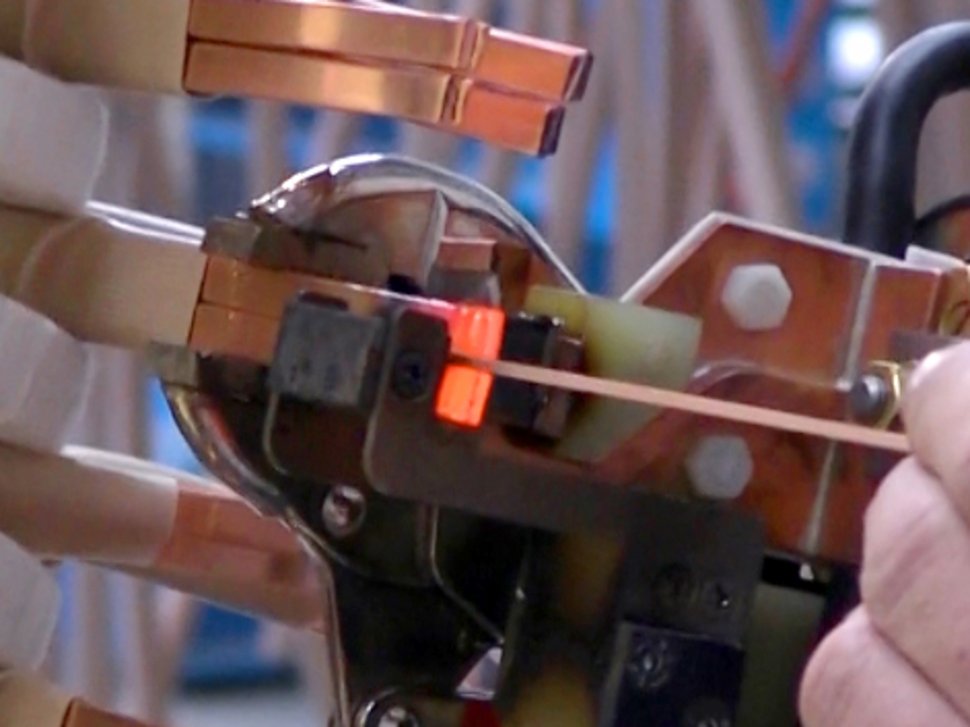

Electrical Mechanical Engineering

Hardening and shrink-fitting of steam turbine components, tightening and releasing of housing elements, thread connections and pipe connections as well as brazing of copper components such as transformer plates, pipe connections, short-circuit rings and braded wires in a wide range of sizes. These are the induction heating processes used in electrical engineering.